News

Contact Us

Quanzhou DAFON Machinery Co.,Ltd.

Mob:+86 15059560663

Website:hanencg.com

Add: Hailian Industrial Park, Shuitou Town, Nan'an City, Fujian Province, China

Industry News

What are the advantages and disadvantages of machine-cut stone

Time:2021-06-25 09:00:03 Source: Views:974 Font-size:16px | 14px | 12px

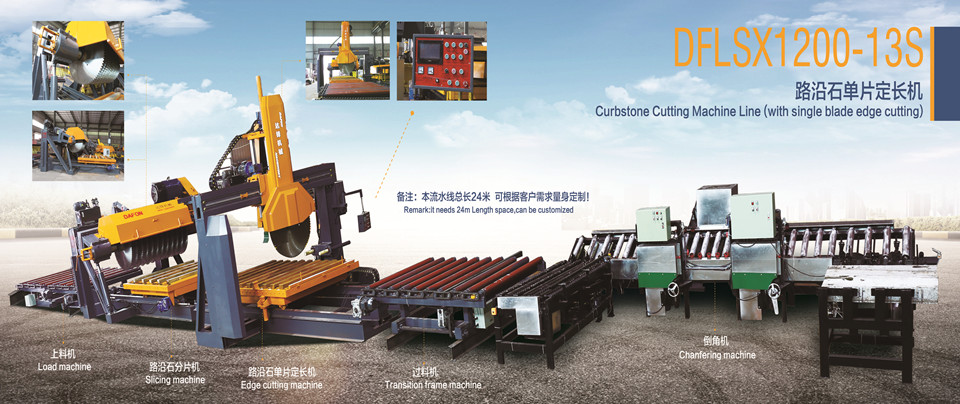

Machine-cut stone refers to the slab that has not been processed after being cut by a large saw. Machine-cut stone is generally used as capstone, curbstone, slab cutting machine garden low wall, stair riser, etc. where pedestrians and vehicles are not allowed. Machine-cut marble cutting machine surface stone has its advantages and disadvantages.

The advantage of machine-cut surface stone is that it is cheap. The price of stone is related to the variety and processing complexity of the stone, and the machine-cut surface is completed after simple cutting, so the price of the machine-cut surface of the same stone is the cheapest. It is precisely because of this that the machine-cut surface is widely used in some public projects, such as curbstones on the roadside, capstones for flower beds in parks, walls, and other places where the amount of use is not high for decoration.

The defect of machine-cut surface stone is that it is non-slip and has a saw pattern on the surface. The non-slip is due to the flat surface of the slab after being cut by the big saw. If the floor is laid directly, people and vehicles will simply slip and fall on it. The saw blade of the big saw is made of diamond, and there must be a certain amount of wear when cutting the stone. Therefore, there may be some slight arc-shaped textures on the surface of the stone diamond cutting machine when cutting the stone, which is not cutting marble tile beautiful enough if you look aluminum cutting machine closely.